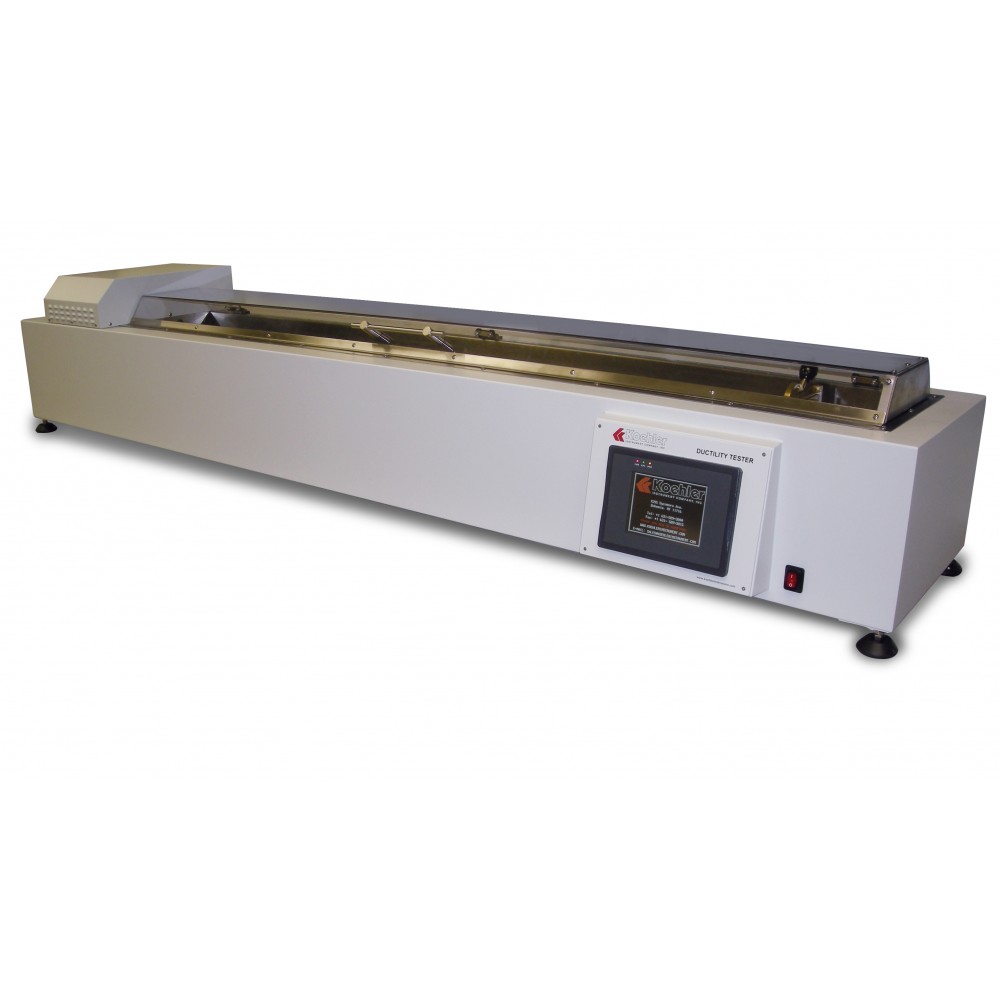

Semi-Automatic Ductility Testing Machine

Determines the ductility of a bituminous material by measuring the distance in which a sample will elongate before breaking when two ends of a briquet specimen of the test material are pulled apart at a specified speed and temperature. Elastic recovery is determined by pulling the briquet specimen to a specified distance at a specified speed and temperature. The briquet is then cut and the distance in which it takes for the two halves to reconnect is used to determine the elastic recovery of the test sample.

- Conforms to ASTM D113, D6084 and related specifications

- Standard and Constant Temperature Models available

- Capable of testing up to three samples simultaneously

- 6” LCD Touch Screen Control Panel

- Pre-programmed with Ductility, Recovery, and Custom test methods

- Maximum travel length of 150 cm

- Variable traction speed from 0.25 to 7.0 cm/min

- Constant Temperature model equipped with Lexan Cover for enhanced temperature stability

The Semi-Automatic Ductility Testing Machine is designed explicitly for testing the ductility and elastic recovery of bituminous materials. It features a 6” LCD touch screen control panel. This integrated touch screen allows the user to choose between the ductility or recovery test methods. The custom menu allows for the input of desired speed and time parameters. During testing, the distance traveled by the specimen is displayed and a simple touch of the screen can record the distance traveled upon breakage of the briquet. A motor jogging feature permits locking of the sample carriage without additional movement after the briquet sample is loaded into the machine.

Standard Model:

- Standard Mold (3)

- Base Plate

Constant Temperature Model:

- Circulation Bath

- Remote Temp. Probe, 10 ft. length

- Connection Tubing

- Standard Mold (3)

- Base Plate

- Lexan Cover

Conforms to the specifications of:

ASTM D113, D5892, D6084, P226; IP 32, 516; DIN 52013, EN 13398; NF T 66-006; AASHTO T 51, T 301; JIS K2207; ANS A37.11; Federal Specification SS-R-406C; USDA Method 5 (BUL 12-16)

Capacity: 3 molds with samples

Maximum Travel Length: 150 cm

Standard Traction Speed: 5 cm/min

Variable Traction Speed: 0.25 to 7.0 cm/min

Timer: 1-999 min

115V 60Hz

220-240V 50Hz

220-240V 60Hz

lxwxh,in.(cm)

Standard Model: 861⁄4x19x16 (219.1 x 48.3 x 40.6)

Circulation Bath: 153⁄4x81⁄4x221⁄2 (219.1 x 48.3 x 40.6)

Constant Temperature Model: 861⁄4x19x16 (219.1 x 48.3 x 40.6)

Net Weight:

Standard Model: 200 lbs (91.7kg)

Circulation Bath: 50 lbs (22.7 kg)

Constant Temperature Model: 217 lbs (98.5 kg)

Standard Model:

Shipping Weight: 350 lbs (159kg)

Dimensions: 92 3⁄4x 2 51⁄4x 23 1⁄4” (235.6 x 64.1 x 59.1cm)

Constant Temperature Model:

Shipping Weight: 368 lbs (167kg)

Dimensions: 9 3⁄4x 25 1⁄4x 23 1⁄4” (235.6 x 64.1 x 59.1cm)

- K80012 Standard Mold

- K80041 Recovery Mold

- K80013 Base Plate

- 250-000-63F ASTM 63F Thermometer, Range: 18 to 89°F

- 250-000-63C ASTM 63C Thermometer, Range: -8 to 32°C

- K80050-SFW Semi-Automatic Ductility Software