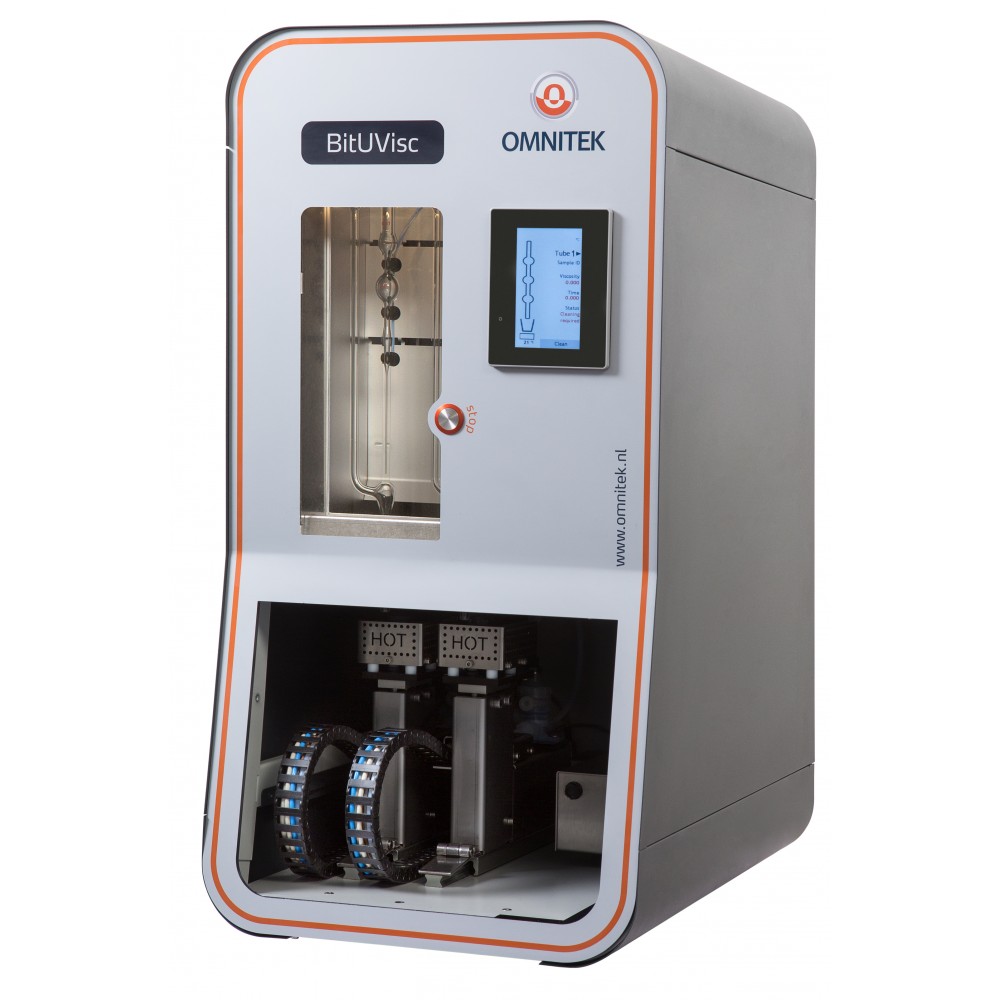

Omnitek BitU-Visc Automatic Viscometry System

Kinematic viscosity characterizes flow behavior. This method covers the procedure for the determination of kinematic viscosity of liquid asphalts, road oils, and distillation residues of liquid asphalts at high temperatures.

- Applicable for fuels, base oils, formulated oils, highly viscous samples like vacuum residues, additives, crude oils, waxes, heavy fuel oils, polymers, asphalts, etc.

- Meets all ASTM, EN, ISO, DIN, AASHTO T201 and standards related to kinematic viscosity

- Extremely accurate temperature control

- Extremely accurate flow-time measurement independent of fluid type

- Viscometer filling by vacuum method

- Innovative and efficient viscometer tube cleaning allowing cross contamination free operation

- Easy viscometer tube exchange

- Chemically resistant to an extended range of fluids and solvents

- Compact design

The Omnitek BitU-Visc is a programmable, fully automatic kinematic viscometer specially designed to handle highly viscous samples at high temperatures. The system can process samples with viscosities ranging up to 120,000 mm2/s, up to 150 C.

There are 2 different models available: BitU-Visc 110 features a single thermostatic bath with 1 viscometer tube whereas the BitU-Visc 120 model holds 2 viscometer tubes in a single bath. All BitU-Visc instruments are equipped with auto-sampling, preheating, fully automatic dual solvent cleaning and drying.

The viscometer tubes are based on the well-known and proven Ubbelohde design. Using specially designed thermal sensors, these tubes allow the detection of fully opaque fluids without any problems or limitations and eliminate the need to use reverse flow tubes. The standard configuration offers viscosity measurement up to 150 C and sample preheating up to 200 C.

Sophisticated temperature control ensures that measurements are carried out well within the required temperature stability. The system features an innovative single position auto-sampling which provides integrated heating of the sample up to 200 C and uses preheated solvent to effectively clean the viscometer tube. The BitU-Visc is fitted with specially designed duplo viscometer tubes for unstable samples such as vacuum residues, additives, crude oils, waxes, heavy fuels oils, polymers, asphalts, etc., which typically show poor determinability when sampled repeatedly. These tubes have 2 measuring sections with an approximately similar tube constant. This allows for an actual duplo determination while only sampling once.

The BitU-Visc requires a PC (not included) for full operation and can be controlled through an advanced PC software application but it can also be controlled as a stand-alone unit through the responsive color touchscreen interface with a storage up to 10,000 measurement results. The PC software allows the operator to specify optimized and fully customizable test methods for each individual sample. For data collection, storage, calculations, and reporting, an advanced PC application is provided with the instrument, which can gather data from up to 4 instruments simultaneously.

The BitU-Visc utilizes advanced and easy to use multilingual software. One PC can control multiple systems (1 COM-port required for each instrument). Data can be exchanged with a LIMS via RS232 or via wireless. The instrument can be operated in its entirety through the PC interface. Sample ID's can be loaded and sample queues can be started, halted or temporarily suspended. Results are automatically stored in the internal database and also can be stored on any external drive or network folder.

During a run, several kinds of information are shown like measured flow times (average and corrected), percent difference, viscosity result, bath temperature, set temperature, preheater temperature, sample ID, test method, measuring section and last results. Also, actual status like filling, cleaning, etc., is shown for every unit involved. Measured flow times are presented in left or right column, depending on whether the upper or lower measuring bulb is used for testing.

- Single Position Autosampler with tube preheater

- Duplo Viscometer Tube(s)

- Bath Oil

- Dual Solvent Injection

- Reference Standards

- Advanced PC Software

Conforms to the specifications of:

ASTM D445, D446, D2170; AASHTO T201; IP 71; ISO 3104, ISO 3105; DIN 51562; FTM 791-305; NF T 60-100

Measuring Range: Up to 120,000 mm2/s, up to 150 °C

Temperature Range: 15 to 150 °C (59 - 302 °F)

Temperature Stability: 15 - 100 °C ±0.01 °C; Up to 150 °C ±0.03 °C (*For temperatures around ambient, an external chiller is required)

Timer Accuracy: 0.001 s

Sample Volume: 12 mL

Sample Introduction: Vacuum

Solvent Consumption: 20 - 30 mL per cycle, sample dependent

Sample throughput:

BitU-Visc 110: Up to 2 measurements per hour

BitU-Visc 120: Up to 4 measurements per hour

** Measurements per hour depends on the viscosity, tube, temperature and solvents chosen

Viscometer Type: Ubbelohde based

Sensor Type: Thermal

Communication: RS232

PC Control: Multiple instruments can be controlled with one PC

Data Export: USB

115V 60Hz

230V 50Hz

wxdxh,in.(cm)

BitU-Visc 110/120: 15 x 24.4 x 30.7 (38x62x78)

Net Weight

BitU-Visc 110/120: 119.05 lbs (54 kg)

- Pedestal Base

- Cooling Circulator (for measurement around room temperature)

- Compressor

- PC for Instrument Control

- Glass Sample Cups (50/pack)

- Duplo Viscometer Tubes

- Spare Parts Kit