RPVOT (RBOT) Oxidation Test Apparatus

The RPVOT (RBOT) procedure employs severe oxidation conditions to rapidly determine oxidation stability. Suitable for both new and in-service oils, the RPVOT (RBOT) method is applicable to many types of petroleum oils. The sample is oxidized in the presence of water and a copper catalyst in a stainless steel pressure vessel under an initial pressure of 90psi (620kPa). Pressure inside the vessel is recorded electronically or mechanically while the vessel is rotated at 100rpm at constant temperature, and the amount of time required for a specified drop in pressure is the oxidation stability of the sample. A variation of the RPVOT (RBOT) method is the “Thin Film Oxidation Uptake Test” (TFOUT) for gasoline automotive engine oils.

- 2, 3 and 4-unit systems

- Oxidata® Pressure Measurement System

- Conforms to ASTM D2112, D2272 and IP 229 specifications for RPVOT (RBOT) testing

- Conforms to ASTM D4742 specifications for TFOUT testing

Constant temperature bath rotates oxidation pressure vessels at 100rpm at an angle of 30° in accordance with ASTM specifications. Includes drive system and oil bath with electronic solid state temperature control. Meets ASTM requirements for heat transfer capability and temperature control precision. A convenient carriage arrangement allows the oxidation vessels to be inserted quickly and securely in the drive system. A strong magnet holds the vessel in place while locating pins in the carriage engage the base of the vessel. PTFE guides support the pressure vessel stem for added stability. If the vessel becomes obstructed for any reason, the magnetic carriage releases it to prevent damage. A chain and sprocket drive system powered by a heavy duty capacitor start motor rotates the vessel carriages at 100rpm. Drive shafts ride on PTFE fluorocarbon bearings which provide extended service and are compatible with silicone heat transfer fluids and other types of bath oils. The bath temperature is controlled within ASTM specified limits by an electronic solid state controller with °C/°F switchable digital setpoint and display. Over-temperature protection is provided by a built-in limit control that automatically interrupts power to the bath when the bath liquid temperature exceeds 16.7°C (30°F) above the temperature setting or 177°C (350°F). Power must then be manually restored by the operator after checking the cause of the problem. The pressure vessel carriage vanes circulate the bath oil during testing to ensure temperature uniformity, and an auxiliary stirrer can be operated between tests to prevent sludging of non-silicone bath oils. The bath interior is constructed of welded stainless steel and is fully insulated.

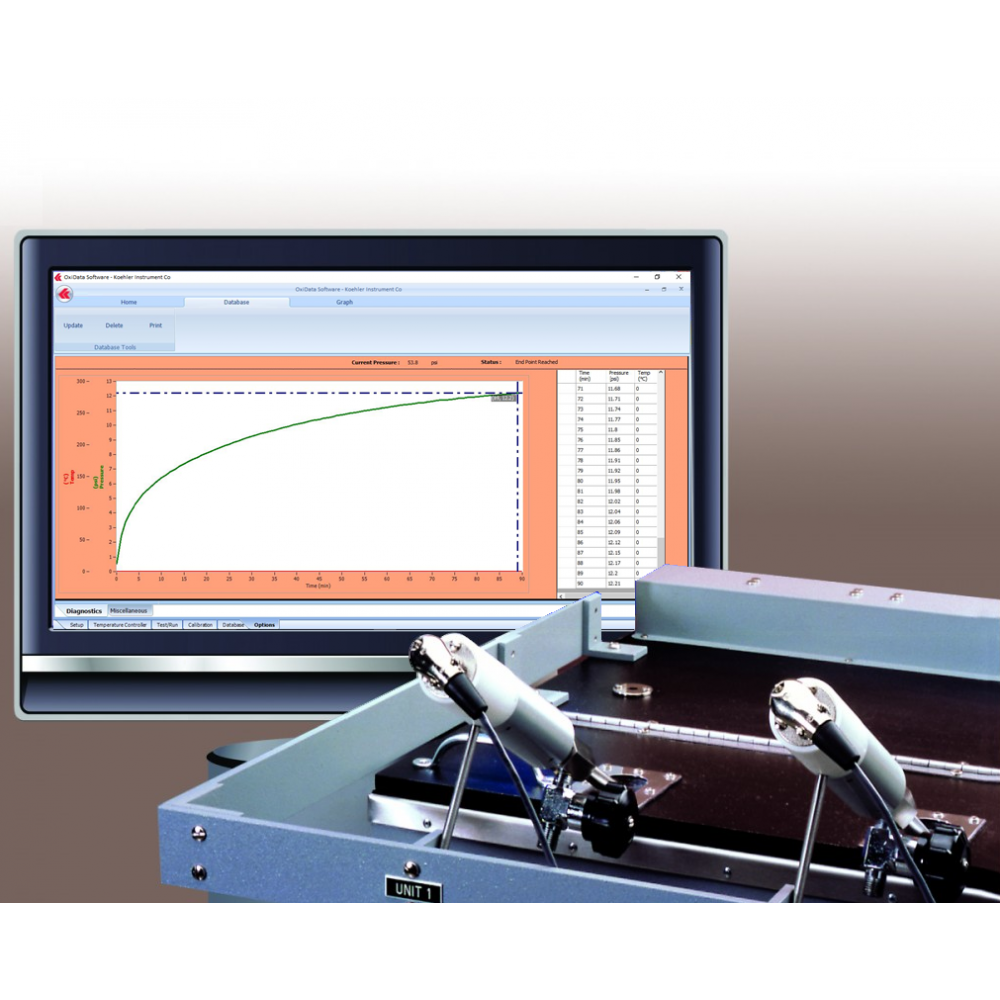

A hinged section of the bath cover provides easy access to the vessel carriages. Vapor barriers in the cover close around the vessel stems to contain vapors from the hot bath medium. A chemically-resistant polyurethane finish protects the bath exterior and control cabinet. The Oxidation Pressure Vessel consists of pressure vessel body, cap and stem with inlet needle valve in accordance with ASTM specifications. The vessel holds one borosilicate glass sample container between two PTFE discs. The closure ring tightens by hand to seal cap to pressure vessel body. The vessel connects to a pressure recorder or rotary transducer and rotates on magnetic carriage in RBOT bath. Withstands working pressure of 500psi (3450kPa) per ASTM specifications. A stainless steel construction ensures proper rate of heat transfer. The closure ring is constructed of chrome plated steel. Includes PTFE fluorocarbon wear disc and sample container cover disc. Includes Oxidata® Pressure Measurement Systems, which are electronic pressure measurement systems exclusively designed for RPVOT (RBOT), TFOUT and other ASTM oxidation test methods. Powerful Oxidata software for Windows environments. Monitors up to twelve pressure and four temperature channels. It can be installed to most manufacturer’s RPVOT(RBOT)/TFOUT test apparatus. Complete electronic measurement systems for plotting pressure versus time and temperature in RPVOT (RBOT) and TFOUT testing. Each system includes transducers, pressure vessel couplings, RTD probe assembly, multiplexer, data acquisition card, software, and mounting and connecting hardware. Systems are available in two, three and four pressure vessel configurations, and additional channels can be added for up to a total of twelve.

Conforms to the specifications of: ASTM D2112, D2272, D4742; IP 229

Capacity: 2, 3 or 4 oxidation pressure vessels

Temperature Control:

Maximum Temperature: 200°C (392°F)

Control Stability: ±0.02°C (±0.04°F)

Heater Range:

2 and 3-pressure vessel models: 0-2750W

4-pressure vessel models: 0-3750W

Recommended Bath Medium: high temperature silicone heat transfer fluid

Drive System: 100rpm positive drive transmission powered by a continuous duty 1⁄2hp ball bearing motor with built-in gear reducer

Bath Capacity:

K70200/K70290 18gal (68L)

K70300/ K70390 25gal (95L)

K70400/ K70490 32gal (121L)

Capacity:

K70200/K70290 2 oxidation vessels

K70300/ K70390 3 oxidation vessels

K70400/ K70490 4 oxidation vessels

115V 60Hz, Single Phase, 10.2A

220-240V 50/60Hz, Single Phase, 5.3A

lxwxh,in.(cm)

K70200/ K70290: 28x26x33 (71x66x84)

K70300/ K70390: 37x26x33 (94x66x84)

K70400/ K70490: 46x26x33 (117x66x84)

Net Weight:

K70200/ K70290: 237 lbs (107.5kg)

K70300/ K70390: 284 lbs (129kg)

K70400/ K70490: 375 lbs (170kg)

Shipping Weight

2 Vessel Unit: 400 lbs (181.4 kg)

3 Vessel Unit: 420 lbs (190.5 kg)

4 Vessel Unit: 527 lbs (239.1 kg)

Dimensions

2 Vessel Unit: 40x33x35 in. (101.6x83.8x88.9 cm)

3 Vessel Unit: 34x52x32 in. (86.4x132.1x81.3 cm)

4 Vessel Unit: 59x34x43 in. (149.9x86.4x109.2 cm)

- K70000 Oxidation Pressure Vessel

- K70092 Aluminum Insert - Converts standard K70000 Oxidation Pressure Vessel for use in the TFOUT method

RBOT/TFOUT Oxidata Pressure Measurement System

- K70502-OPS Two-Unit System, 115V 60Hz

- K70592-OPS Two-Unit System, 220-240V 50/60Hz

- K70503-OPS Three-Unit System, 115V 60Hz

- K70593-OPS Three-Unit System, 220-240V 50/60Hz

- K70504-OPS Four-Unit System, 115V 60Hz

- K70594-OPS Four-Unit System, 220-240V 50/60Hz

Sample Beakers

- K70040 RPVOT (RBOT) Sample Beaker Borosilicate glass, 175mL. Meets ASTM D2112, D2272 specifications

- K70091 TFOUT Sample Container Borosilicate glass. Meets ASTM D4742 specifications

Oxygen Charging Accessories

- K70080 Charging Hose. 6 ft (1.8m), with connections

- K70082 Female Quick Disconnect Coupling, for charging hose

- K70081-1 Male Quick Disconnect Coupling, 1⁄4" NPT, for oxidation pressure vessel

- K70013 Oxygen Pressure Regulator

Oxidation Pressure Vessel Accessories

- K70050 Silicone O-ring - Replacement seal for pressure vessel lid-body connection

- K70049 Sample Beaker Cover (PTFE disk)

- K70048 TFOUT Sample Beaker Cover (PTFE disk)

- K70000-03008 Spring. Inserts in pressure vessel to hold RPVOT (RBOT) beaker and cover in place

- K700-0-3A Spring. Inserts in pressure vessel to hold TFOUT container and cover in place

Copper Catalyst for RPVOT (RBOT) Method

- K70030 Copper Catalyst Coil Prepared in accordance with ASTM specifications and packed in a sealed glass container with nitrogen atmosphere. Ready to use.

- K70090 Copper Catalyst Wire - 1.63mm electrolytic copper wire in 500 ft (152m) lengths.

- K70002 Winding Mandrel - Machined aluminum mandrel for winding copper wire into coils meeting ASTM specifications. Mounts on K70003/K70004 Drive Unit

- K70003 Drive Unit for Winding Mandrel - Slow speed gear motor mounted on a sturdy base. Facilitates coil winding procedure. 115V

- K70004 Drive Unit for Winding Mandrel - Similar to K70003 but for operation on 220-240V

Catalyst Package for TFOUT Method

- K70093 Catalyst Package A - For simulating IIID engine test. Includes 3 catalyst packages

- K70095 Catalyst Package B - For simulating IIIE engine test. Includes 3 catalyst packages

Pressure Vessel Support Racks

- K70017 Pressure Vessel Support Rack, 2-Unit

- K70011 Pressure Vessel Support Rack, 3-Unit

- K70012 Pressure Vessel Support Rack, 4-Unit

Pressure Recording Equipment

- K70010/24 Pressure Recorder, 24-hour

- K70018 Replacement Cartridge Pen

- 308-000-004 Recorder Chart, 24-hour Box of 60 charts

Thermometers

- 250-001-37C IP 37C Thermometer. Range: 144 to 156°C - For RPVOT (RBOT) method.

- 250-000-96C ASTM 96C Thermometer. Range: 120 to 150°C - For ASTM D2112 method.

- 250-000-100C ASTM 100C Thermometer. Range: 145 to 205°C - For TFOUT method.