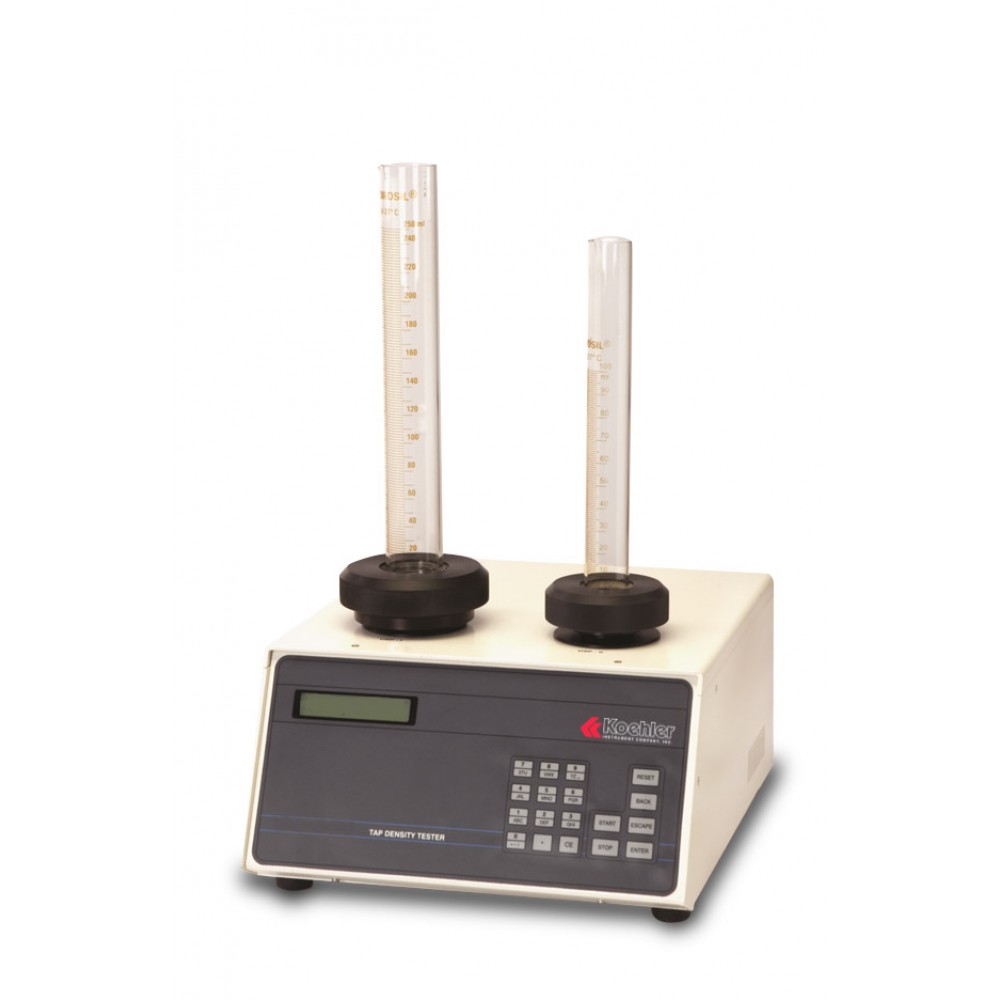

Tap Density Tester

This test measures increased bulk density attained after mechanically tapping a graduated measuring cylinder or vessel containing a powder sample. After observing the initial powder volume or weight, the measuring cylinder or vessel is mechanically tapped, and the volume or weight readings are taken until little further volume or weight change is observed

- Designed to meet current USP and ASTM Specifications fortap density testing.

- The unique simultaneous tapping and rotating motion assures that the material is evenly packed.

- Calculates test results – Tapped Density, CompressibilityIndex, Hausner Ratio, and Bulk Density.

- Two cylinder holders will hold 100 mL and 250 mL cylinders.

- Balance interface for sample weight transfer.

The Tap Density Tester is advance microcontroller based with user friendly software in dialog mode. The Alpha-Numeric splash proof keyboard allows entries such as sample name, sample number or ID number for data authentication. The report printout complies with GLP requirements and a built-in Real Time Clock provides date, time display, and authenticity of the printout.

Test Method:

USP Method I (300 taps per minute)

USP Method II (250 taps per minute)

ASTM (optional)

Tap Count Range: 10 – 9999

Type of Drive: Direct Drive with stepper motor.

Drop Height:

USP I: 14 ± 2 mm

USP II and ASTM: 3 ± 0.3mm

Platform Rotation: 5 – 15 rotation/minute

Display: 20 x 2 Lines, Back light LCD Display

Keyboard: Alphanumeric, splash water proof, polyester soft keys

Operating Modes: USP, user selectable

Output: Printer, RS-232C, Parallel Port, PC Connectivity for Data Downloading

Power Requirement: 230V / 50 Hz, 45W

Environmental Operating Conditions:

Operation: Indoor

Temperature: Ambient to 45°C

Humidity: 20% to 80%

Cylinders: 1 each, 100 mL and 250 mL

Cylinder Holders: 1 each for 100 mL and 250 mL

115V

230V

wxdxh in.(cm): 13.4 x 12.2 x 7.9 (34 x 31 x 20)

Shipping Weight: 29 lb. (13 kg)