Thank You for Your Interest in the NLGI HPM Specification!

Koehler Instrument Company is proud to offer a wide variety of products for your HPM Testing needs

FEATURED KOEHLER HPM TESTING PRODUCT

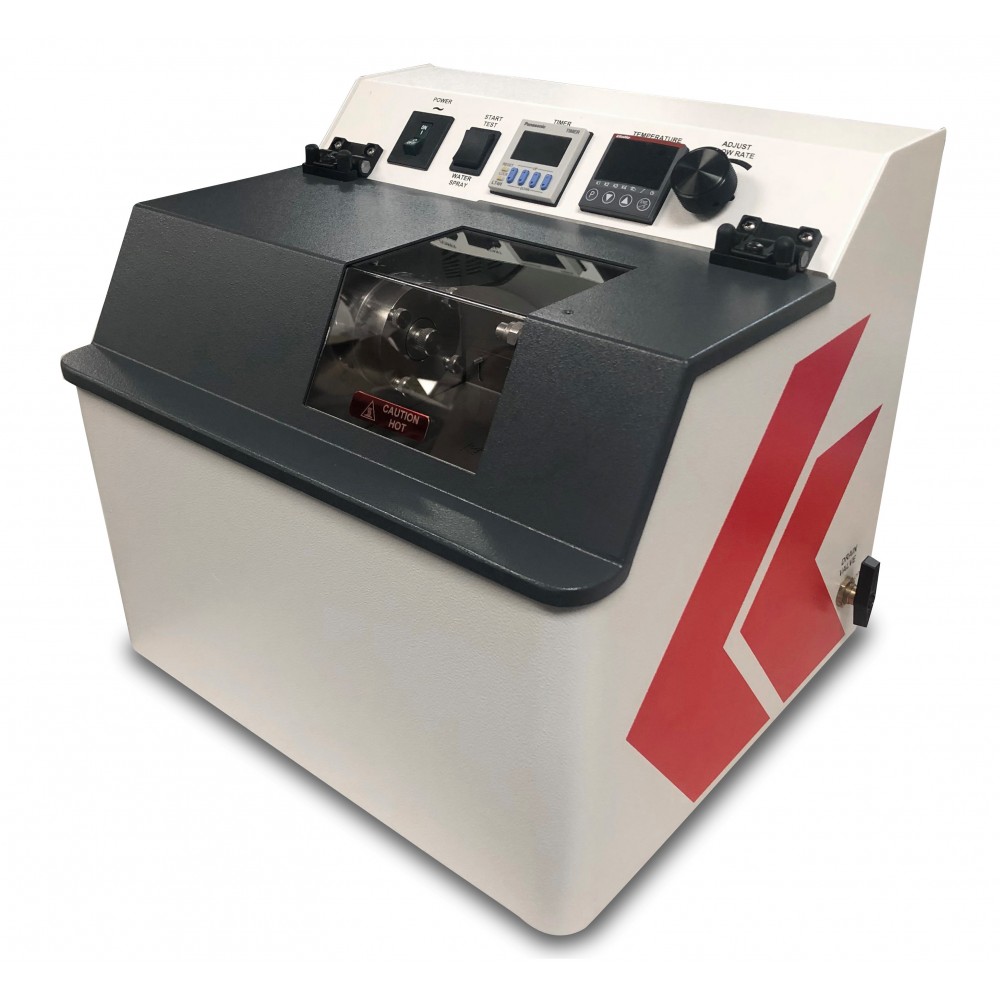

Water Washout Tester

HPM | HPM + WR

ALL KOEHLER HPM TESTING PRODUCTS

HPM |

|

Digital PenetrometerMicroprocessor-based penetrometer loaded with advanced features to provide ease of operation and highly reproducible consistency measurements of petroleum products as per ASTM D217. |

HPM |

|

Oxidation Stability Test Apparatus for Lubricating GreasesConstant temperature oil bath holds pressure vessels at the proper depth for determining oxidation stability of lubricating greases as per ASTM D942. |

HPM |

|

Water Washout TesterRotates a lubricated ASTM ball bearing at 600rpm in a modified bearing/housing assembly while impinging the bearing with a jet of water at the specified flow rate and temperature as per ASTM D1264. |

HPM |

|

Low Temperature Torque ApparatusSignificant for the design and specification of greases for low temperature service, the low temperature torque test measures the extent to which a grease sample retards rotation of a bearing assembly at the test temperature as per ASTM D1478. |

HPM |

|

Oil Separation Apparatus – Constant Temperature Air CabinetDetermines the tendency of a lubricating grease to separate oil during storage in a 35 lb pail as per ASTM D1742. |

HPM |

|

Oil Separation ApparatusConsists of 60 mesh nickel gauze cone with wire handle, tall form 200mL beaker and cover with hook. The sample is placed in the wire gauze cone and weight loss is determined after heating at test temperature for specified time period as per ASTM D6184. |

HPM |

|

Roll Stability TesterRoll stability apparatus for shear stability tests on lubricating greases. Rotates steel test cylinders at 10 or 165rpm in a thermostatically controlled environment at temperatures of up to 200°F (93.3°C) as per ASTM D1831. |

HPM |

|

Benchtop Four Ball Wear and EP TesterThe K93170 Four Ball Wear and EP Tester is designed as per ASTM standards to conduct tests to determine the coefficient of friction of lubricants, wear preventative (WP) and extreme pressure (EP) properties of lubricating oils under a variety of test conditions as per ASTM D2266 and D2596. |

HPM |

|

Corrosion Preventive Properties ApparatusDistributes a lubricating grease sample in a roller bearing by running the bearing under light thrust load. Corrosion preventive capability is determined on a pass/fail basis by the presence of rust spots (1mm or larger) on the bearing race after a 60 second run-in period followed by prolonged exposure to water at constant temperature as per ASTM D1743. |

HPM |

|

Corrosion TesterThe Corrosion Tester K9445X has been developed for testing lubricating greases on their corrosion inhabiting characteristics in rolling bearings in the presence of either distilled or demineralized water, or salt water or synthetic sea water and under no applied load as per ASTM D6138. |

HPM |

|

Copper Strip Corrosion from Lubricating GreaseConstant temperature bath immerses 20 test jars for lubricating greases as per ASTM D4048. |

HPM + WR |

|

Water Washout TesterRotates a lubricated ASTM ball bearing at 600rpm in a modified bearing/housing assembly while impinging the bearing with a jet of water at the specified flow rate and temperature as per ASTM D1264. |

HPM + WR |

|

Water Spray ApparatusComplete Water Spray Apparatus meets ASTM specifications and includes spray chamber, delivery system and constant temperature reservoir. Sprays water at the specified rate and temperature on a test panel coated with sample grease as per ASTM D4049. |

HPM + CR |

|

Corrosion Preventive Properties ApparatusDistributes a lubricating grease sample in a roller bearing by running the bearing under light thrust load. Corrosion preventive capability is determined on a pass/fail basis by the presence of rust spots (1mm or larger) on the bearing race after a 60 second run-in period followed by prolonged exposure to water at constant temperature as per ASTM D5969. |

HPM + CR |

|

Corrosion TesterThe Corrosion Tester K9445X has been developed for testing lubricating greases on their corrosion inhabiting characteristics in rolling bearings in the presence of either distilled or demineralized water, or salt water or synthetic sea water and under no applied load as per ASTM D6138. |

HPM + HL |

|

Benchtop Four Ball Wear and EP TesterThe K93170 Four Ball Wear and EP Tester is designed as per ASTM standards to conduct tests to determine the coefficient of friction of lubricants, wear preventative (WP) and extreme pressure (EP) properties of lubricating oils under a variety of test conditions as per ASTM D2266 and D2596. |

HPM + HL |

|

SRV®5 Test SystemThe basic SRV®5 oscillation system – a practical solution for practical problems. This leading worldwide test system allows high-precision investigation of friction and wear in lubricants and materials as per ASTM D7594. |

HPM + LT |

|

Low Temperature Torque ApparatusRefrigerated two-unit apparatus for ASTM low temperature torque tests on lubricating greases as per ASTM D1478. |

HPM + LT |

|

Low Temperature Grease Flow TesterThe Low Temperature Flow Tester, K95300, has been developed for testing lubricating greases in low temperature environments. The test is performed in accordance with DIN 51805 and can also be customized. |